OLMA was established in 1946. The main facility is located on a 25,000 sq. meter area - 12,000 of which are indoor and subdivided in two groups of production facilities.

OLMA first core business was the production of roll forming machines. It soon developed its own manufacturing range for the production of trapezoidal and sinusoidal profiles, welded pipes and transfer plants for the production of components for the home appliances industry.

At the beginning of the Seventies, to meet the technological requirements of a changing market, OLMA decided to enter the field of home appliances and specifically the production of transfer plants to manufacture cabinets, panels and doors for refrigerators, washing machines, dish washers, freezers, waters heaters, and a variety of other applications.

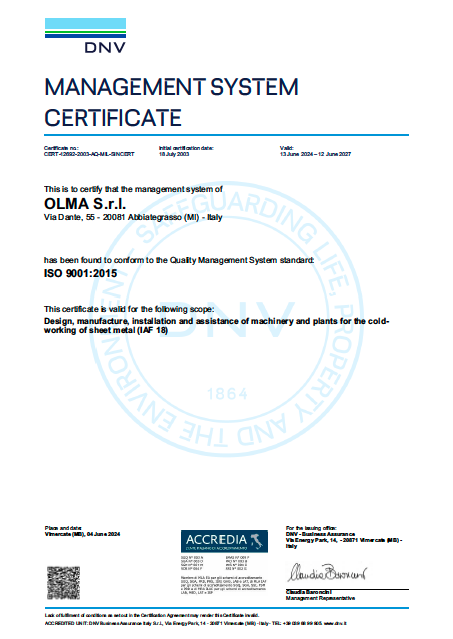

OLMA has been producing and supplying quality goods and services in compliance with the rules and guidelines of UNI EN ISO 9001 since 2003.

OLMA history has been characterized by innovation and meeting Customers’ requirements from the beginning, developing machines that are considered the benchmark in the industry of sheet metal working.

The new generation high flexibility bending stations ALLbend, ACbend and ATbend were developed based on more than 70 years of experience in the field.

Austria

Belarus

Bulgaria

Denmark

Finland

France

Germany

Greece

Hungary

Italy

Lithuania

Macedonia

Malta

Montenegro – Yugoslavia

Poland

Portugal

Romania

Russia

Slovakia

Slovenia

Spain

Sweden

Ukraine

United Kingdom

China

India

Iran

Iraq

Jordan

Korea

Lebanon

Pakistan

Saudi Arabia

Syria

Thailand

Turkey

Australia

Argentina

Bolivia

Brazil

Canada

Chile

Colombia

Dominican Republic

Mexico

Peru

U.S.A.

Venezuela

Algeria

Egypt

Morocco

Nigeria

South Africa

Tunisia